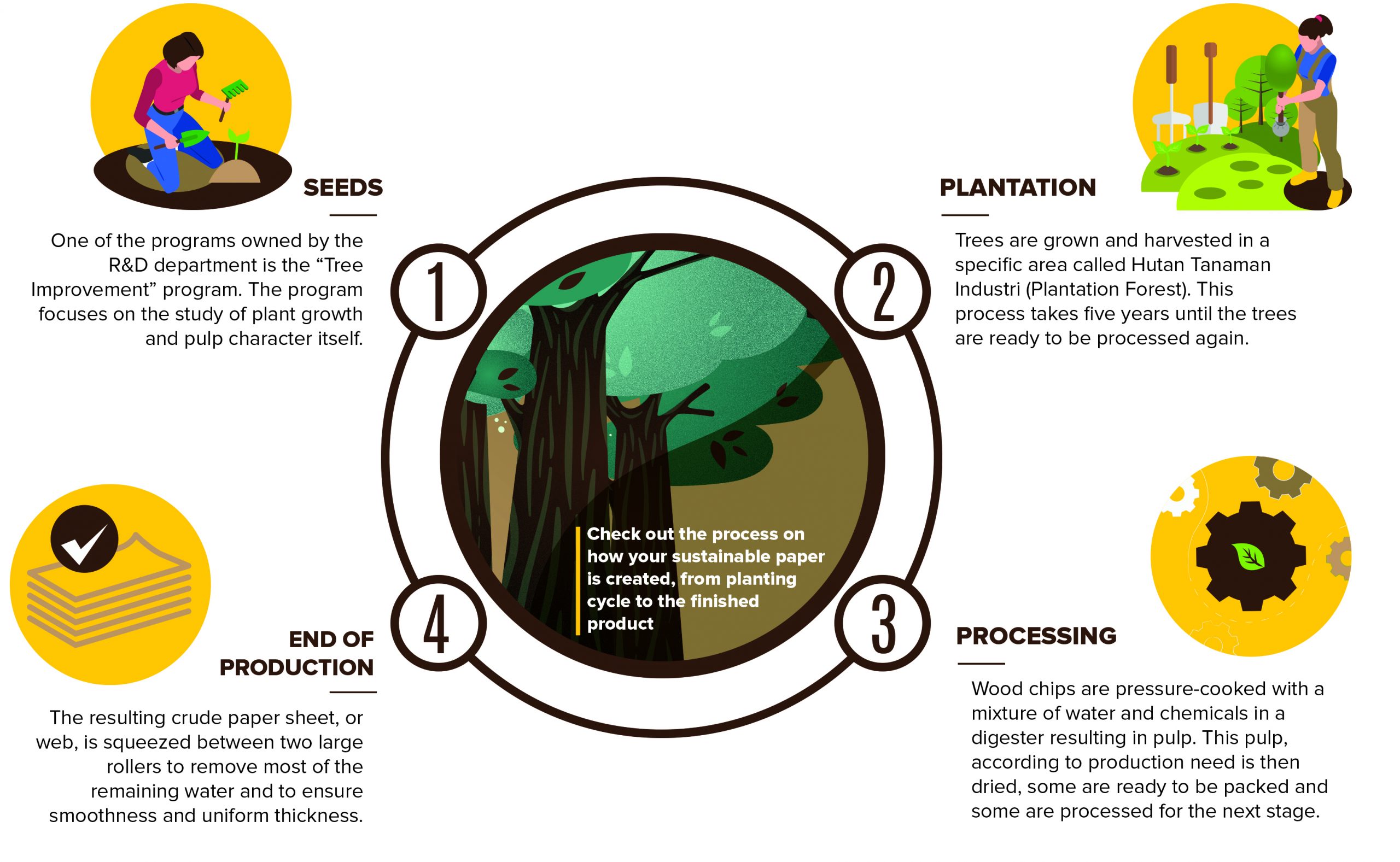

Check out the process on how your sustainable paper is created,

from the planting cycle to the finished product

The paper products that we see in our everyday lives come from a tiny seed that grows into a tree. The seeds that are being planted in our plantations follow Sustainable Forest Management and are controlled by the constant technology-improved by our research and development team. We believe that research and development is one of the essential components for achieving sustainable plantation management.

Read More

Our R&D department activities aim to produce the world’s superior seeds and plants that carry out our missions to increase competitiveness, productivity, and research to address issues faced in plantation management.

One of the programs owned by the R&D department is the “Tree Improvement” program. The program focuses on the study of plant growth and pulp character itself. The main goal of this program is to identify the breed and production of seed crops that are superior by adopting the latest technology.

Show Less

Trees are grown and harvested in a specific area called Hutan Tanaman Industri (Plantation Forest). This process takes five years until the trees are ready to be processed again.

Read More

ACACIA (Acacia Crassicarpa) tree – is a common sight in Indonesia, where it is widely used by the pulp paper industry. Its fiber is particularly well suited for making paper and is widely used for writing paper, packaging, cardboard, and others. It’s a fast-growing tree. In the fertile soils and warm climate of Indonesia, a tree can be ready for harvest in as little as five years. Acacia also helps fix the soil structure, helping prevent floods and landslides. This is especially important in hilly or mountain areas, but the tree also does well in lowlands.

Show Less

To begin the process, the bark is removed from the wood through chippers where spinning blades cut the wood into wood pieces. The bark that is removed can be used as biomass fuel. Wood chips are pressure-cooked with a mixture of water and chemicals in a digester resulting in the pulp. Pulp, according to production needs, some are dried, some are ready to be packaged and some are processed for the next stage, processed into paper and various derivative products.

As the pulp travels down the screen, water is drained away and recycled. The resulting crude paper sheet, or web, is squeezed between two large rollers to remove most of the remaining water and ensure smoothness and uniform thickness. A slitter cuts the sheet into smaller, more manageable rolls depending on the products.

Read More

It’s our commitment to customer satisfaction. We believe tradition and modernity go hand in hand in our business. We highly value long term relationships as part of our Eastern traditions, while we also are eager to embrace the modern values of innovation and efficiency.

Show Less

Please Fill Up The Below Details!

A product of:

PT. Indah Kiat Pulp & Paper, Tbk.

Jl. Raya Minas – Perawang KM.26,

Pinang Sebatang, Perawang

Kec. Tualang, Kabupaten Siak

Riau 28685

BUSSINESS CONTACT

A ZERO DEFORESTATION COMMITMENT

We believe in creating a sustainable future through our products and we are doing our part to chart the path ahead through our Forest Conservation Policy launched on 5 February 2013.

www.asiapulppaper.com

2020 © All rights Reserved. Asia Pulp & Paper (APP) Sinar Mas